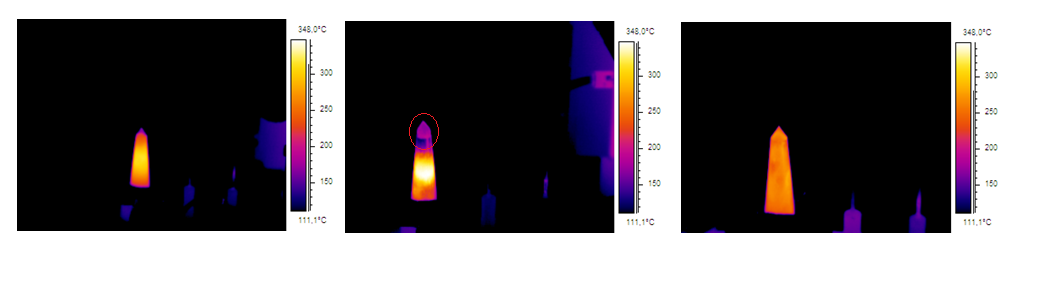

In this research the goal was to see if machine vision could be applied on classifying veneer quality. Requirements were as many faults as possible in veneers could be recognized with a single machine vision system. The study was carried out by imaging the veneers with near-infraredspectral camera, 5 Mpixel smart camera, near-infrared camera and a line scan camera. The biggest challenge was the width of the veneers, which could be over 2 meters. Following image shows few faults that the veneers typically have.

In near-infrared spectral imaging is based on finding the differences between substances. Faults in the veneers and good veneers may not be from different materials. Also the resolutions in spectral cameras is quite small, which means that veneers which are 2 meters wide won’t be imaged accurately. Because of these reasons, it was decided that spectral imaging wouldn’t be the applied technology in this case.

The best smart camera on the market (5Mpixel greyscale smart camera from Cognex) was used when imaging the veneers. The resolution of the camera was enough if the veneers would be imaged in two sections. Only problem was that the software did not have the tools for this accurate quality control.

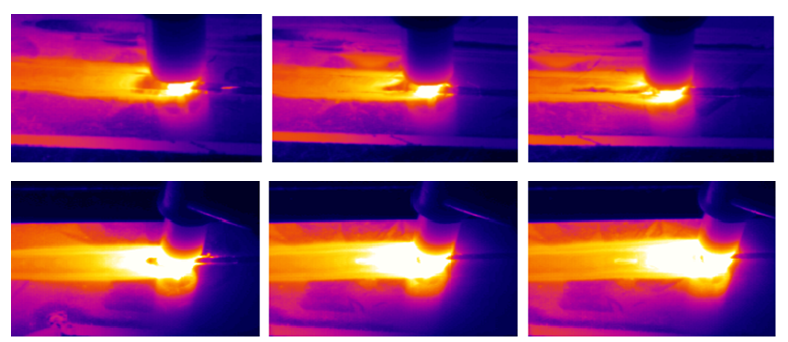

Near-infrared imaging showed quite early on that the resolution was a big problem. Also the infrared spectrum provided pretty much no added information compared to greyscale images. No furthermore testing were done on the infrared camera because of the reasons said above.

Linescan camera showed promising results. If the linescan camera is chosen with the big enough resolution, even when imaging big veneers it wouldn’t be a problem. When imaging with a linescan camera, either the camera needs to be move, so it can “scan” the veneers. Analyzing the images of the veneers is challenging even when using a linescan camera, but when for example HALCON-machine vision software library, it has possibility to analyze the faults because of the wide range of algorithms it has built-in.

As the result for this study, can clearly be said that only applicable option is using a color linescan camera combined with either HALCON-imaging library or MATLAB-software or develop a whole new algorithm from scratch for it.