Central cores are manufactured with a method called hotbox. Hotbox method means that a sand mixture is blasted into a warmed up central core box. The central core is dried out in a box where heat is transferred through heat plates on the sides and also from the bottom with the help of the central core support. One cell robot cell that manufactured central cores produced different quality cores. Robotic cell’s problem was figured out when the central cores heating element was inspected with a thermal imaging camera. After imaging the central core, immediately the uneven heat spread was noticed.

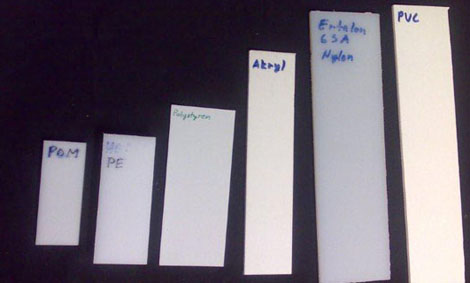

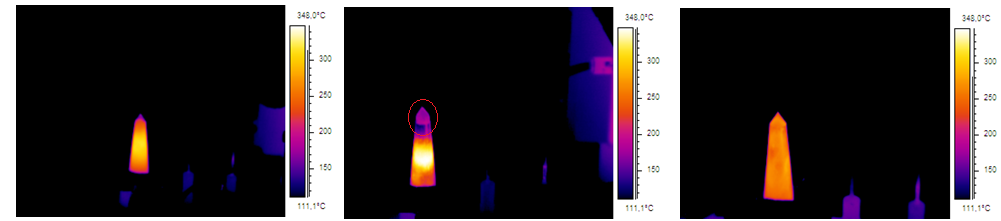

The molds in which the central cores are made, are not measured temperature wise, but an average temperature is set with a adjustable resistor. Thus the temperatures inside the core are never known. Temperature range between different parts of the mold could be various dozens, which meant that the mold’s tip was notably cooler than any other part of the mold (Image 1). First thing that was made to the mold, was that the tip was changed to a copper one and everything else was left steel. After doing several tests with this new mold, immediately a more even heat spread around the tip could be noticed. But still the temperature would change drastically on the steel part of the mold (Image 2). As a final change, every part of the mold was changed into a copper. Thus the temperature would spread very evenly, as seen in the image (Image 3).

After the thermal imaging inspections and the changes were made, the robotic cell’s production rate was increased drastically.